-

Menyoroti

FF 807 Bright Acid

,Tin Plating Process Bright Acid

,FF 807 Bright Tin Plating Additive

-

JenisTimah Asam Cerah

-

MenggunakanPelapisan timah

-

barangbahan pembantu kimia

-

FiturRentang operasi yang luas

-

Tempat asalCina

-

Nama merekFENGFAN

-

Nomor modelFF-807

-

Kuantitas min OrderBisa dinegosiasikan

-

Hargadapat dinegosiasikan

-

Kemasan rincianKemasan standar ekspor

-

Waktu pengiriman15-25 hari kerja

-

Syarat-syarat pembayaranL/C, D/A, D/P, T/T, Western Union, MoneyGram

-

Menyediakan kemampuan200000pcs/hari

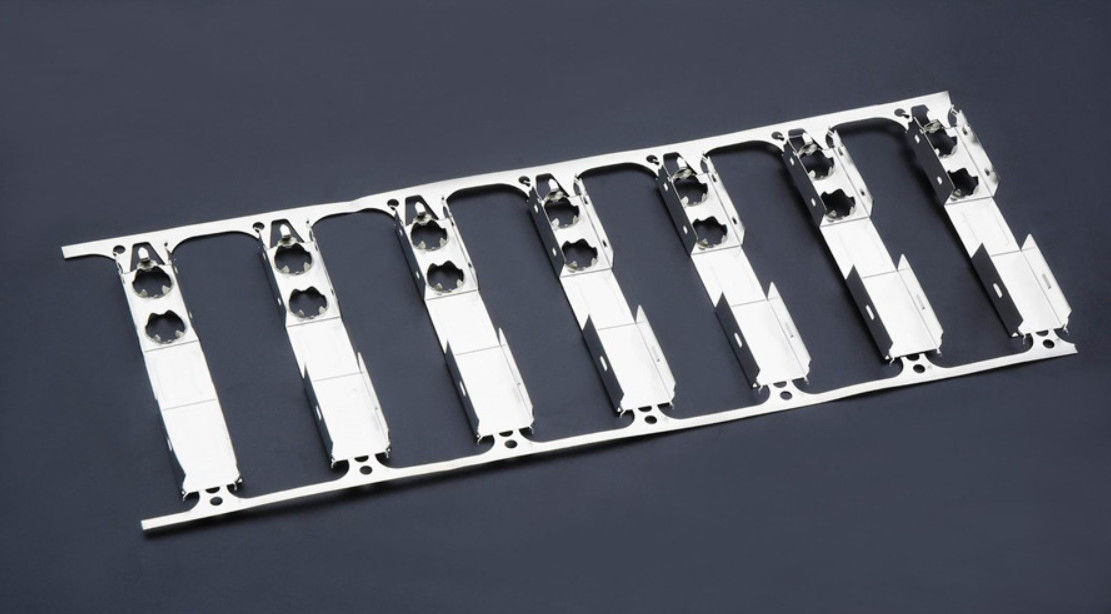

FF-807 Bright Acid Tin Plating Process Manual Production Line

FF-807 Bright Acid Tin Plating Process (manual production line)

FF-807 bright tin plating additive can produce a mirror-bright coating. The anti-tarnish coating has excellent corrosion resistance and weldability, and is suitable for rack plating and barrel plating. The acid tin bath is highly stable and easy to maintain.

Features:

• Wide operating range.

• The plating solution is highly stable.

• Even after storage, it still maintains good ductility and weldability.

• Low consumption of additives.

Bath composition:

| Range | Optimal | |

| Stannous sulfate | 24-35g/L | 30g/L |

| Sulfuric acid | 90-110ml/L | 100ml/L |

| FF-807A carrier | 20-40 ml/L | 30 ml/L |

| FF-807B brightener | 2-6 ml/L | 3 ml/L |

Operation condition:

| Rack plating | Barrel plating | |

| Temp | 20-30℃ | 25℃ |

| CCD | 0.5-3.5A/dm2 | 0.5-1.0 A/dm2 |

| ACD | 1.0-2.0 A/dm2 | 1.0 A/dm2 |

| Fiteration | Recommended | |

| Agitation | Cathode movement | |

| Anode | 99.99% pure tin | |

Bath preparation:

1) Add 3-5% by volume sulfuric acid and 1.0 ml/liter FF-807A carrier to the plating tank to settle overnight. Then rinse thoroughly with clean water.

2) Add half of the distilled water or deionized water to the plating tank, and add 10% chemical pure sulfuric acid in the plating tank.

3) While stirring, add appropriate amount of stannous sulfate and distilled water. Add water to make up the water level and cool to room temperature.

4) Add appropriate amount of FF-807A carrier and FF-807B brightener. At this time, the preparation of the plating solution is completed and can be used for production.